Hazel 4D | turntable pallet wrapping machines

Atlanta EvA, Synthex, & Mytho Easy

These Atlanta semi-automatic turntable stretch wrapping machines are ideal for securing heavy and unstable pallet loads with stretch film.

They’re designed to wrap pallets quickly and save operators time and effort.

We have a range of turntable machines to suit all kinds of requirements. From the Mytho Easy, designed for high-volume pallet wrapping, to the simple core brake Eva turntable wrapper, perfect for wrapping small volumes of pallets.

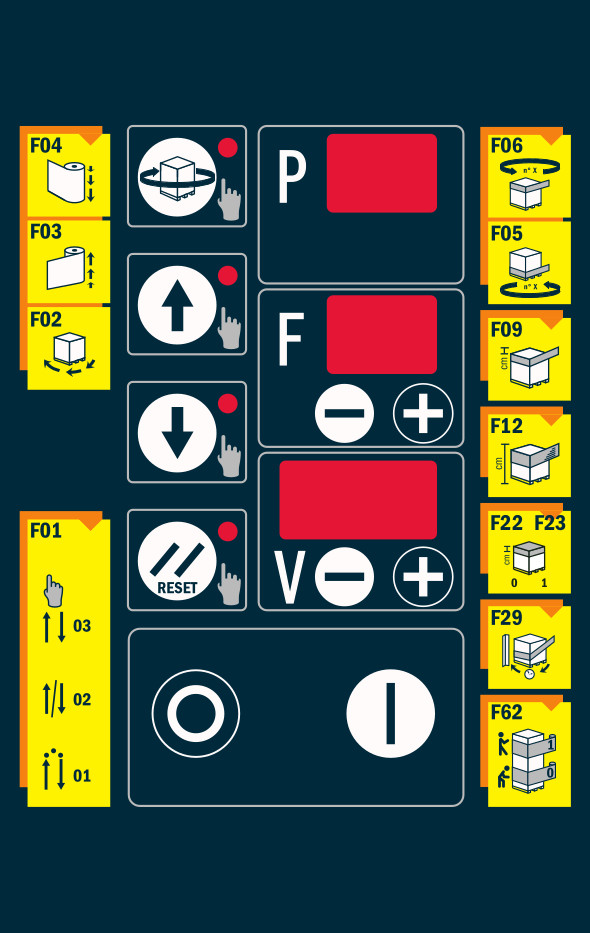

standard Features adjustable from the control panel:

|

|

|

|

|

|

|

|

Low profile available for mytho & Synthex machines

No need to dig a hole in your warehouse floor!

The 25mm low profile turntable makes it easier to push pallets onto the turntable by hand, using a pallet truck. The ramps ensure unstable pallets don't fall over.

The low profile turntale has a small footprint, meaning the machine can still fit into compact spaces.

Mytho Easy turntable pallet wrapper

The Mytho Easy is our most advanced turntable stretch wrapping machine. It’s ideal for high-volume pallet wrapping and securing difficult or awkwardly-shaped loads. It’s capable of stretching pallet wrap up to 400% on application, helping you optimise the stability of your pallets at the most economic price.

It has simplified controls to make it easy to use and also comes in a low profile version.

6 customisable programmes for more control over your pallet wrapping

Technical details

-

11-inch touch screen control panel with password protection

to prevent unauthorised changes -

Maximum pallet weight on turntable:

Mytho Easy: 2000kg, Mytho Easy Low Profile: 1200kg

Additional adjustable features:

-

4 stage film tension

-

Pre-stretch % of the film

-

Multiple reinforcement layers each with independent pre-stretch & tension control

To make sure your pallet loads are as stable as possible,

we recommend using MFNANO12 or MFNANO15

Extremus nano stretch film with your Mytho Easy pallet wrapper.

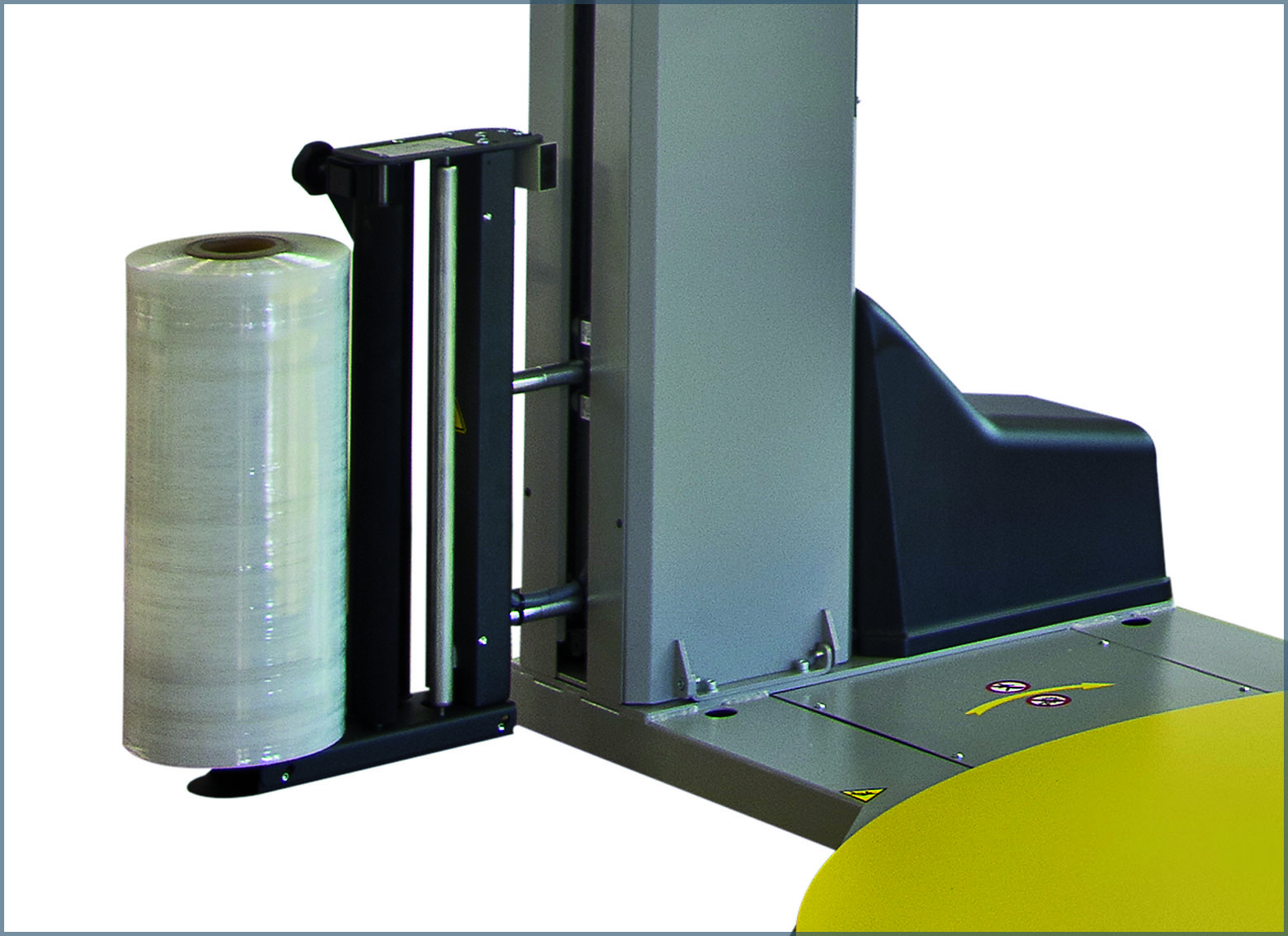

Easy to load film system

Fitted with an easy to load PS Power Stretch film carriage with 2 motors and 3 driven anti-cut polyurethane rollers, the same rollers used on Atlanta's advanced automatic pallet wrappers. The variable pre-stretch system means the machine can stretch film between 120-400%.

Synthex Turntable pallet wrapper

This power pre-stretch wrapping machine has been designed to reduce your cost of ownership. It has a motorised pre-stretch system that stretches your film up to 300% on application and 6 customisable programmes to make wrapping your pallets even quicker.

6 customisable programmes for more control over your pallet wrapping

Technical details

-

11-inch touch screen control panel with password protection

to prevent unauthorised changes -

Low profile option available on request

-

Maximum pallet weight on turntable: 2000kg, Low Profile: 1200kg

-

Added optimisation abilities through 7 individual layer configurations

To make sure your pallet loads are as stable as possible,

we recommend using MFNANO12 or MFNANO15

Extremus nano stretch film with your Synthex pallet wrapper.

Easy to load film system

Fitted with an easy to load geared OPS head including 3

electronically driven anti-cut rollers, one motor and interchangeable

pre-stretch ratios.

EVA turntable pallet wrapper

This semi-automatic core brake pallet wrapper is simple and easy to use. With three wrapping programmes each with adjustable features, it’s perfect for companies looking for a no-fuss reliable pallet wrapping machine to stretch wrap a small number of pallets a week.

"Everyone using the Eva wrapper is impressed with the improved wrapping.

There's less, almost zero, tearing of the stretch wrap."

Facilities and Warehouse Manager, Pharmacy Label Supplier

Technical details

-

Mechanical brake manually adjustable

-

Easy reel change

-

Maximum pallet weight on turntable: 1500kg

-

Standard wrapping height: 2200mm

-

Standard turntable diameter: 1650mm

(optional 1500mm)

Improve your pallet load stability

Not sure if you’re applying your stretch film securely in the most cost-effective manner?

Ask for a Hazel 4D load stability consultant to visit your warehouse. We can help you adjust your pallet wrapping machine settings to get the most out of your stretch film, use less plastic and ensure your pallets are as safe as possible.